500 Hood Road, Suite 320Markham ONL3R 9Z3

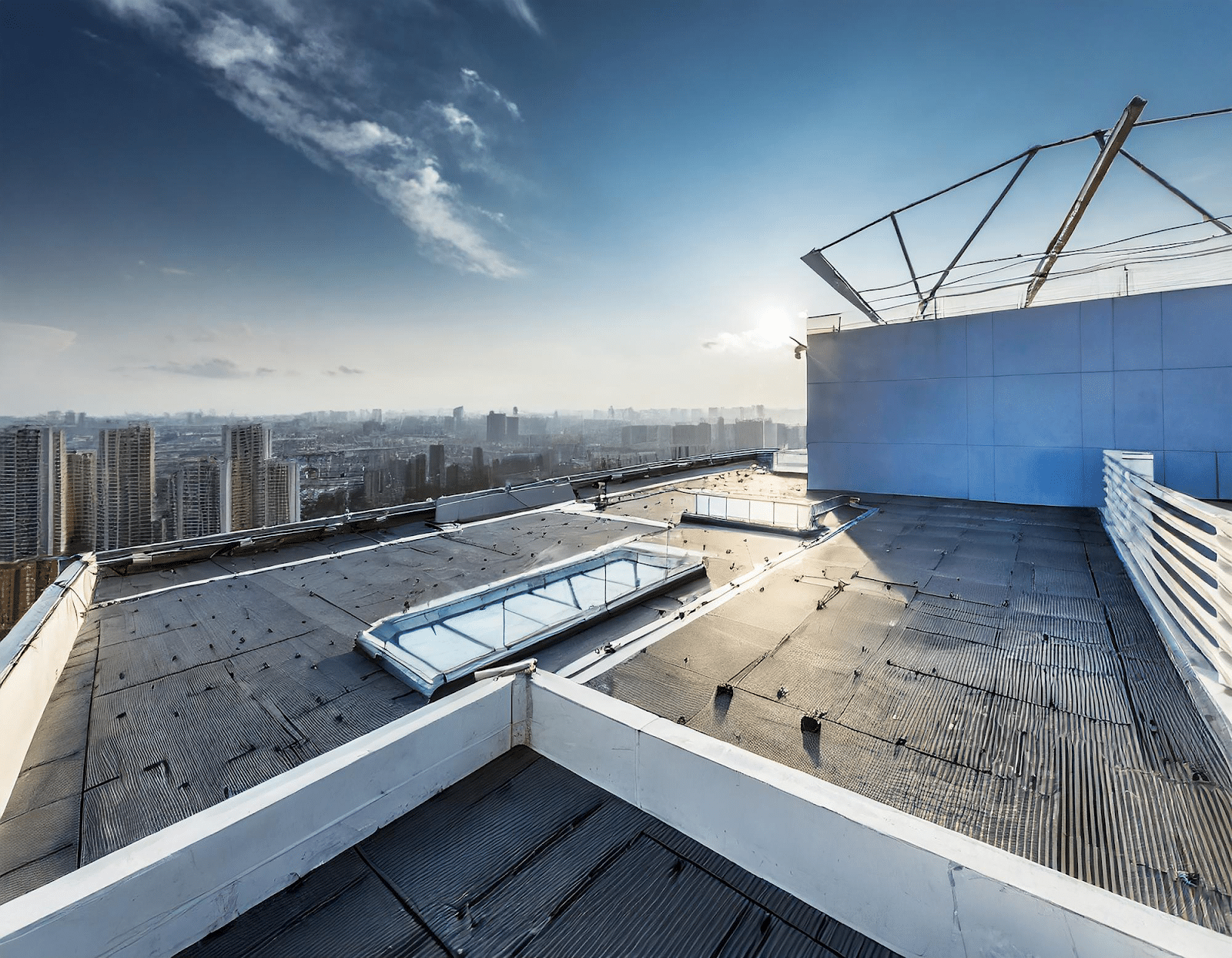

Choosing the best commercial roofing material for your building is crucial for the overall integrity and longevity of your roof. When making this decision, there are several factors to consider, but first and foremost, always work with a professional to help you choose the best commercial roofing material for your specific needs, budget, and more. Other things to consider are the climate you live in, the slope and size of your roof, maintenance requirements, your budget, and your goals. There are many kinds of popular commercial roofing materials and each one has its advantages.

These popular commercial roofing materials are designed to provide durability, longevity, and protection for large buildings such as office complexes, warehouses, retail spaces, and more.

Also referred to as BUR roofing, this common and popular type of commercial roofing is known for its longevity and resistance to weathering. It is made up of multiple layers of bitumen (asphalt or coal tar) and reinforcing fabrics, such as fibreglass or polyester. The layers are built up on top of each other to create a thick, waterproof barrier.

Short for ethylene propylene diene monomer roofing, EPDM roofs are made from a synthetic rubber material that is resistant to UV rays, extreme temperatures, and weathering, making them highly reliable and long-lasting. EPDM roofing is also easy to install and maintain, requiring minimal upkeep over time. Its flexibility allows it to conform to the shape of any roof, providing a seamless and watertight seal that protects the building from leaks and damage.

Green roofing systems are becoming increasingly popular for commercial buildings seeking sustainable and eco-friendly roofing solutions. Green roofs are covered with vegetation and plant life, which helps to reduce energy costs, improve air quality, and reduce stormwater runoff. Green roofs also provide additional insulation and can extend the lifespan of the roof membrane.

This type of roofing system consists of a liquid-based material that is applied directly onto the surface of a building's roof. This material is typically a seamless, waterproof membrane that forms a protective barrier against the elements, including rain, snow, and UV rays. Liquid-applied roofing is often used as a cost-effective and efficient alternative to traditional roofing materials and can be applied to virtually any type of roof shape or substrate.

This is a durable and long-lasting option. Metal roofing is typically made from materials such as aluminum, steel, or copper, and can be installed in a variety of styles, including standing seam, corrugated, and metal shingles. Metal roofs are known for their resistance to fire, wind, and hail, as well as their energy efficiency and recyclability.

This roofing system is a popular choice for flat or low-slope commercial roofs. These roofs are made of asphalt-based materials that are reinforced with fibreglass or polyester. Modified bitumen roofs are highly resistant to damage from UV rays and weathering, making them a durable and long-lasting option.

This type of roofing material is designed to provide waterproofing and protection for flat or low-sloped roofs. It’s typically made from flexible synthetic materials such as PVC, TPO, or EPDM which are highly resistant to UV radiation, ozone, and chemical exposure. Single-ply membranes are lightweight, easy to install, and offer excellent durability and longevity. They are available in a variety of colours and thicknesses to suit different project requirements.

Made from synthetic materials, this roofing material is lightweight and easy to handle. With their heat-welded seams, thermoplastic roof membranes provide excellent waterproofing capabilities, ensuring that the underlying structure is protected from environmental elements. Their white or light-coloured surfaces also reflect sunlight, reducing energy costs and keeping buildings cool.

This roofing material is made from synthetic rubber polymers that are designed to be durable, flexible, and long-lasting. These membranes are typically installed in a single layer and adhere to the roof substrate using adhesive or heat-welding techniques. Thermoset membranes are known for their resistance to UV rays, ozone, and extreme weather conditions, making them an excellent choice for commercial and industrial buildings. They are also resistant to punctures and tears, providing added protection against leaks and water damage.

Short for thermoplastic polyolefin roofing, TPO roofing is known for its ability to withstand extreme weather conditions, making it an ideal choice for buildings that need strong, reliable protection against the elements. Plus, due to its highly reflective surface, it can help reduce energy costs by keeping buildings cooler and reducing the need for air conditioning.

Professional and experienced engineers and building scientists can assist with material selection and the construction of your building. Choosing the right roofing material should not be taken lightly as there are many factors to consider. You need a reliable roof that will keep you, your employees and the structure of your building safe for many years to come.

Regular roof inspections and maintenance are vital to ensure safety and avoid costly repairs. For over thirty years, ABSI has supported property owners and facility managers across Ontario with roof maintenance, rehabilitation, and renewal. Their expertise spans a range of building types, handling everything from condition assessments and audits to design and construction administration. Partnering with ABSI ensures your roof is well-maintained, durable, and capable of providing long-term protection.

Naji Hassan, a renowned professional in Building Science and Engineering, brings a wealth of knowledge and experience to his field. Educated at Beirut Arab University and Harvard Business School Online, Hassan has honed his expertise in structural and municipal engineering, building science, and business management. As the President of Accent Building Sciences and an experienced Senior Project Manager, he has made significant strides in building envelope engineering, building condition assessments, and energy retrofit programs. His commitment to innovation and excellence is evident in his approach to large-scale project management and his active participation in industry organizations. Hassan is not only a leader in his field but also a prolific writer and thought leader. He regularly shares his insights and experiences through articles on LinkedIn, which can be found at LinkedIn Articles. Additionally, he maintains a blog where he delves deeper into various aspects of building science, accessible at Accent Building Sciences Blog. Outside of his professional pursuits, Hassan enjoys travel, golf, languages, gardening, and music, reflecting his diverse interests and well-rounded character. Naji Hassan's journey in building science and engineering is not just a career but a testament to his lifelong dedication to learning, teaching, and inspiring others in his field.

500 Hood Road, Suite 320Markham ONL3R 9Z3